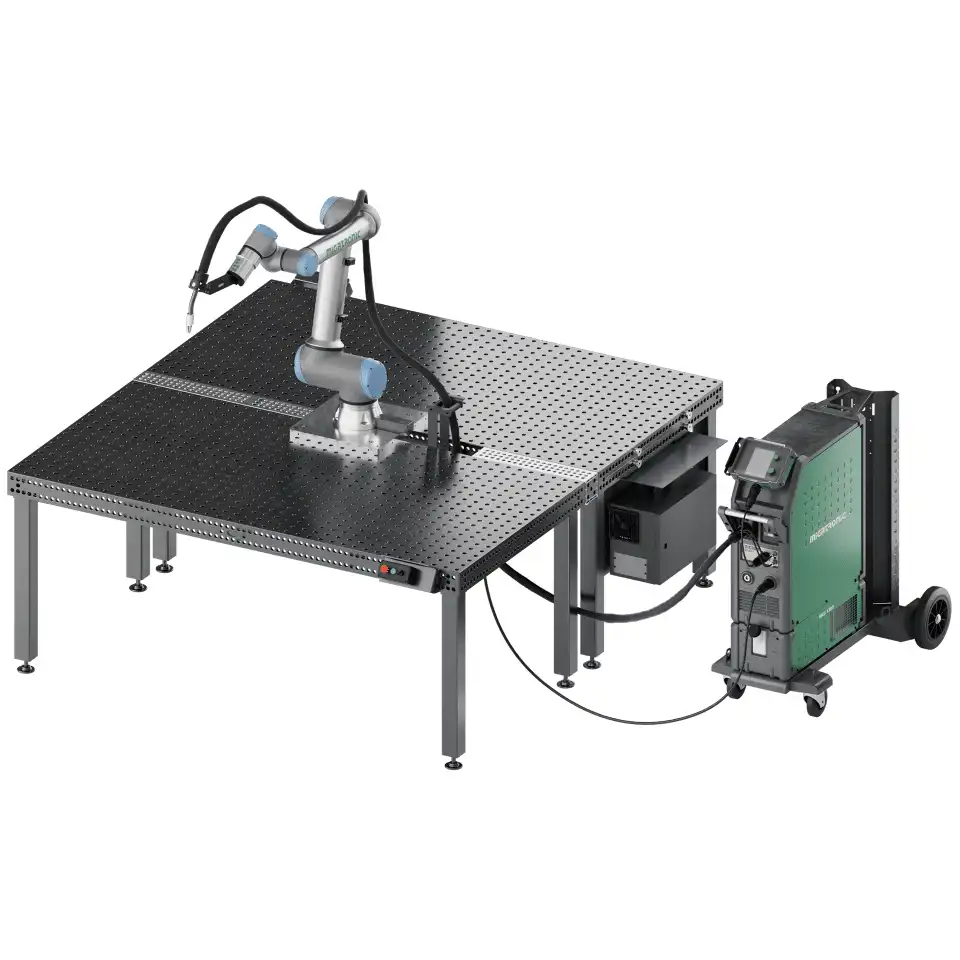

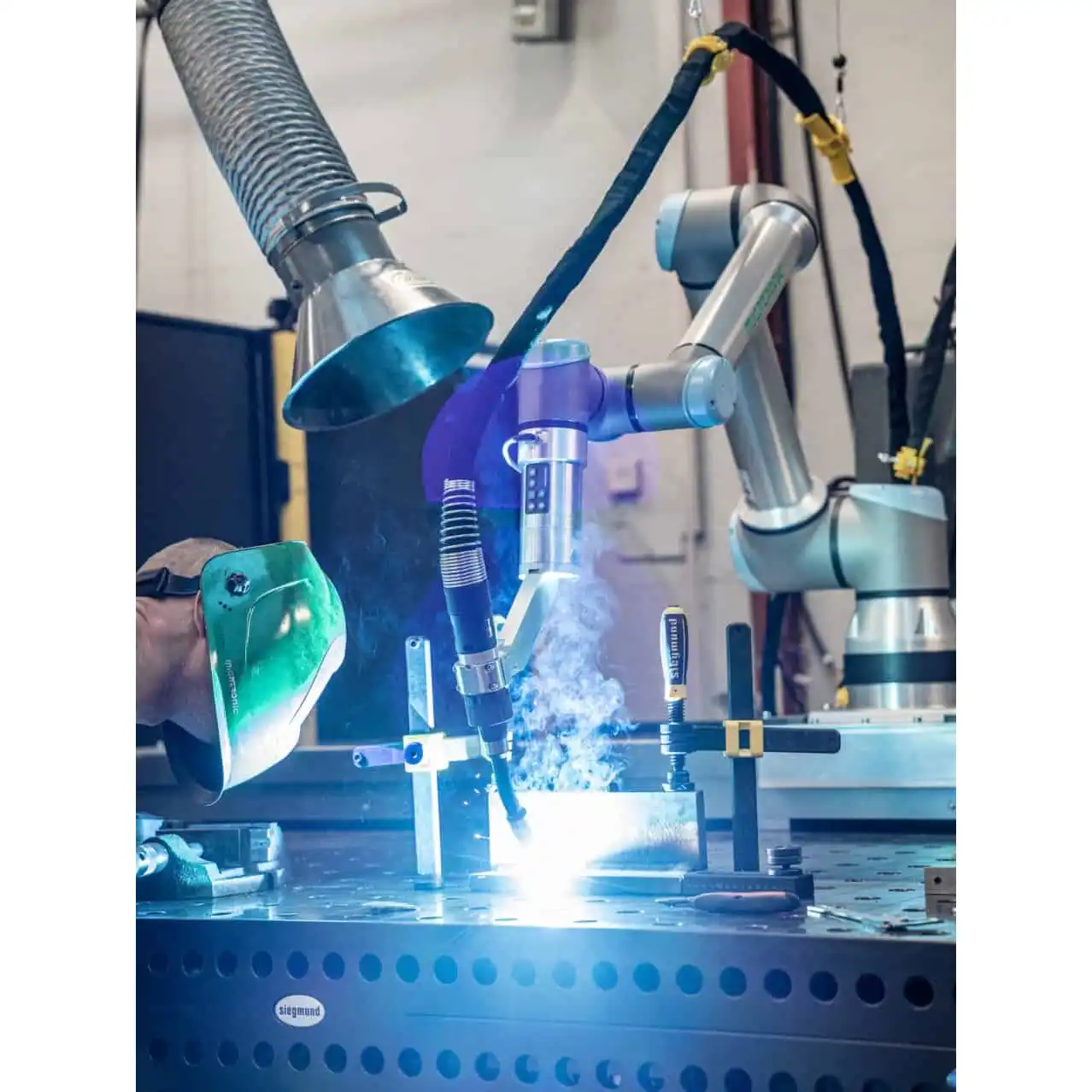

The Migatronic CoWelder is a collaborative welding robot that is perfect for automating small to medium-scale welding production. It is easy to program and use, even for welders with no prior experience with robotics.

The CoWelder is equipped with a variety of features that make it an ideal welding solution for a wide range of applications, including:

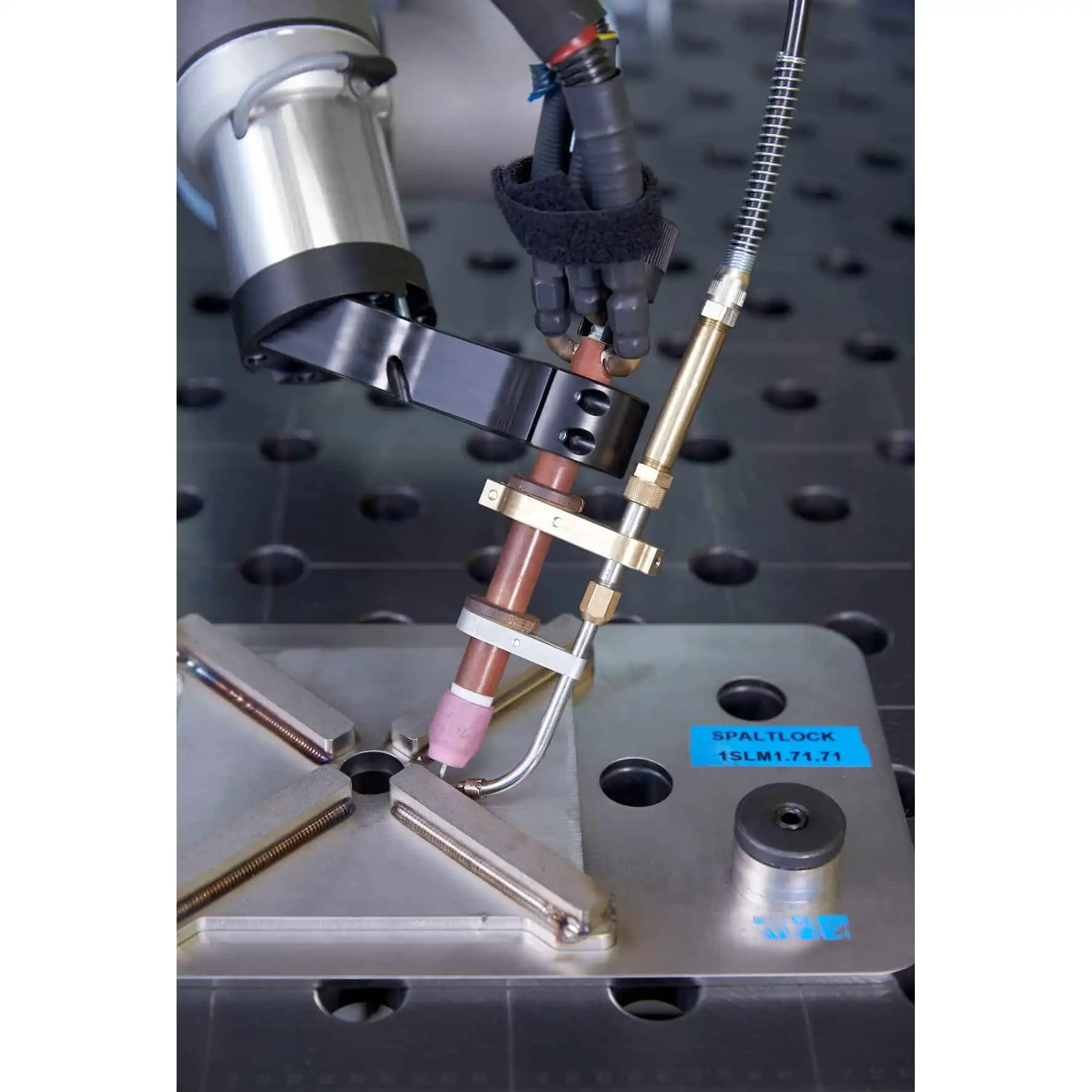

- Six-axis robot arm: The CoWelder’s six-axis robot arm gives it the flexibility to reach and weld in even the most difficult-to-reach areas.

- Easy programming: The CoWelder can be programmed using a simple drag-and-drop interface. This makes it easy to create and modify welding programs, even for users with no prior experience with robotics.

- High welding quality: The CoWelder is equipped with a variety of features that ensure high welding quality, such as precise welding parameters control and arc voltage stabilisation.

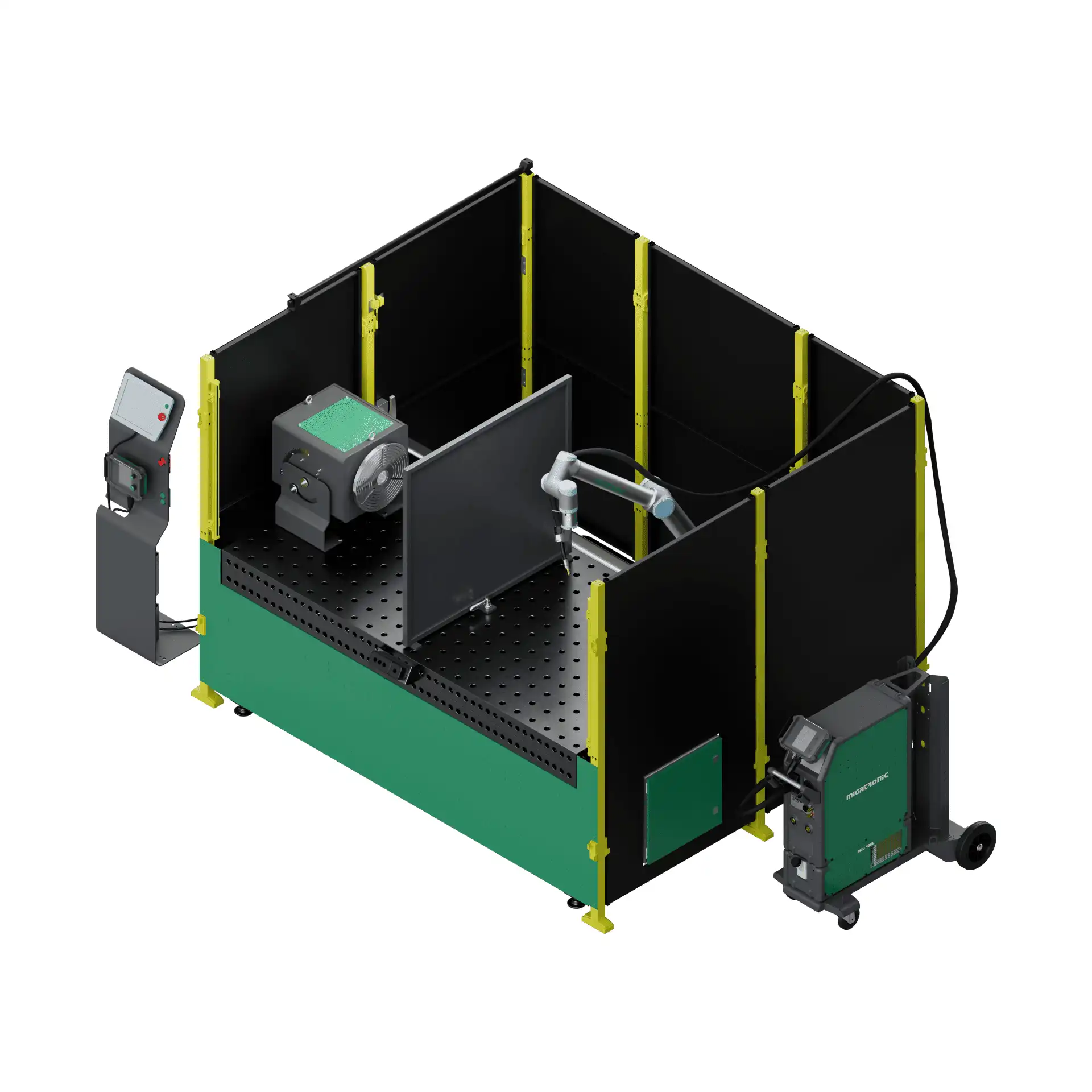

- Safety: The CoWelder is a collaborative robot, which means that it is designed to work safely alongside humans. It is equipped with a variety of safety features, such as collision detection and avoidance.

The Migatronic CoWelder is a powerful and versatile welding robot that can help you to improve your welding production efficiency and quality. It is the perfect solution for a wide range of welding applications, from small batch production to high-volume manufacturing.

Video

Features

- Six-axis robot arm for maximum flexibility and reach

- Easy programming with a drag-and-drop interface

- High welding quality with precise parameter control and arc voltage stabilisation

- Safe operation with collision detection and avoidance

Applications

- Small to medium-scale welding production

- A wide range of welding applications, including fabrication, automotive, and construction