Unleash Precision Cuts with the SWP Straight Line Gas Cutting Machine: Effortless Efficiency for Metal Fabrication

Revolutionise your metal cutting process with the SWP Straight Line Gas Cutting Machine, a portable powerhouse designed for flawless straight cuts on steel plates of 5 to 50mm thicknesses. This user-friendly machine boasts unmatched accuracy and efficiency, making it the ideal choice for professional fabricators, DIY enthusiasts, and anyone seeking effortless metal cutting solutions.

Features

- Portable design: Lightweight and compact for easy transport and setup, ideal for on-site or workshop use

- 110V power supply: Operates on standard household power, eliminating the need for specialised equipment

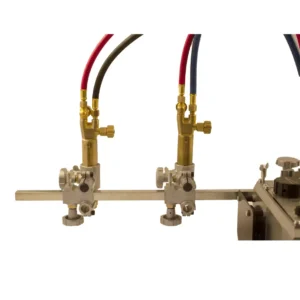

- Durable construction: Built with robust brass and stainless steel components for long-lasting performance

- Simple operation: Intuitive controls and clear markings make it easy to use, even for beginners

- Compatible with oxy-fuel gases: Works seamlessly with oxygen and acetylene or propane for versatile fuel options

What’s In The Box

- SWP 110v Cutting Machine

- 1.8m track

- A-NML 1/32 nozzle

- 3/64 nozzle