This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home / Shop / Gas Supplies / Gas Regulators / Argon Gas Regulators

Buy Now, Pay Later In 3 Interest-Free Payments

Dive into the World of Welding Precision: Explore Our Top-Notch Argon Regulators

Unleash the full potential of your welding projects with the perfect Argon regulator! Here at EWS, we understand the vital role these regulators play in achieving flawless welds, maximising gas efficiency, and ensuring operator safety. That’s why we offer a meticulously curated selection of high-performance argon regulators, catering to both professional welders and DIY enthusiasts.

Whether you’re tackling MIG, TIG, or arc welding, we have the right regulator to match your needs and budget. Explore our diverse range, featuring:

- Single-stage and multi-stage regulators: Choose the optimal level of pressure control for your specific applications.

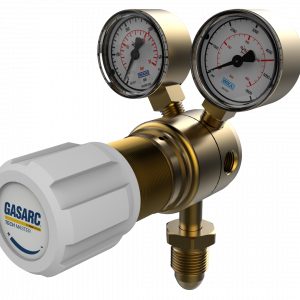

- Durable brass or stainless-steel construction: Invest in robust regulators built to withstand the demands of your workshop.

- NEVOC and other industry-standard connections: Ensure seamless compatibility with your existing gas cylinders.

FAQs

Do I need a special regulator for argon?

Most MIG and TIG welders will specify the argon delivery in litres per minute (lpm) so it is important to make sure that the argon regulator’s delivery gauge reads ‘Flow Rate’.

Regulators must have regular inspections and replaced every 5 year for non-corrosive gases. The body of the regulator is stamped with a date of manufacture. More frequent replacement cycles are required for corrosive gases.

What should argon regulator be set at for MIG welding?

An output of 35 litres per minute (lpm) or higher is ideal for MIG welding. Since turbulent or low flows could contaminate the weld, most welding regulators designed for MIG applications adjust the outlet gas flow to have accurate flow measurements.