This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home / Shop / Gas Supplies / Gas Regulators / Multi Stage Gas Regulators

Buy Now, Pay Later In 3 Interest-Free Payments

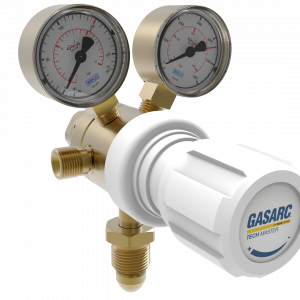

Unleash the consistent flow you crave with our top-of-the-line Multi Stage Gas Regulators! Unlike their single-stage counterparts, these innovative regulators boast superior performance, ensuring a steady, uninterrupted stream of gas regardless of the pressure remaining in your cylinder. This translates to unmatched precision and control for your industrial, medical, or welding applications. Multi Stage Gas Regulators are ideal for high-volume gas users who demand consistent performance. So ditch the frustrating pressure fluctuations and experience the smooth, reliable flow you deserve – browse our extensive selection of Multi Stage Gas Regulators for specific gas types like Nitrogen, Oxygen, CO2, and Acetylene, all featuring high-pressure compatibility and durable construction. Invest in your workflow efficiency and safety with a Multi Stage Gas Regulator today!

FAQs

What’s the difference between a single-stage and a multi-stage regulator?

Both regulators reduce high-pressure gas from a cylinder to a lower, usable pressure. However, a single-stage regulator experiences a drop in output pressure as the gas supply dwindles. This can be frustrating for tasks requiring consistent flow. Multi-stage regulators address this issue by having two (or more) stages of pressure reduction. This ensures a steadier output pressure throughout the life of the cylinder, ideal for precise control in critical applications.

What are the benefits of using a multi-stage regulator?

Multi-stage regulators offer several advantages:

- Consistent Pressure: They deliver a more constant output pressure regardless of the remaining gas in the cylinder. This is crucial for tasks requiring precise control, like welding, medical gas delivery, or laboratory analysis.

- Improved Efficiency: Consistent pressure translates to better tool performance and potentially less wasted gas

- Enhanced Safety: With consistent pressure, you have more control over your equipment, leading to a safer work environment

Who should consider using a multi-stage regulator?

Multi-stage regulators are ideal for applications where consistent pressure is essential. This includes:

- Industrial users: For welding, cutting, purging, and other processes requiring precise gas flow control

- Medical applications: Delivering consistent gas flow for medical equipment like respirators and anaesthesia machines

- Laboratories: Maintaining consistent gas pressure for research and analysis equipment

- High-volume gas users: Anyone who goes through gas cylinders frequently and needs reliable performance throughout the life of the cylinder