This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Home / Shop / Tools / Hand Tools / Welding Clamps & Magnets

Buy Now, Pay Later In 3 Interest-Free Payments

Welding clamps are specialised tools used in welding processes to hold workpieces securely in place during welding operations. They are designed to provide stability and prevent movement or distortion of the workpiece while welding. Welding clamps come in various shapes and sizes, each serving a specific purpose based on the requirements of the welding task.

Types of Welding Clamps

C-Clamps

C-Clamps, also known as G-clamps, are one of the most common types of welding clamps. They have a C-shaped frame with a threaded screw that can be tightened to secure the workpiece. C-Clamps are versatile and can be used for various welding applications.

Locking Pliers

Locking pliers, such as Vise-Grips, have a mechanism that allows them to lock in place and maintain a secure grip on the workpiece. They are useful for holding small parts or materials that may be difficult to clamp with other types of clamps.

Corner Clamps

Corner clamps are specifically designed for holding workpieces at right angles, such as when welding corners or joining two perpendicular pieces. They often have adjustable jaws or swivel pads that allow for different angle configurations.

Magnetic Clamps

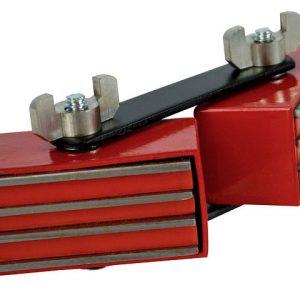

Magnetic clamps use powerful magnets to hold ferrous (magnetic) workpieces in place. They are commonly used in welding applications where traditional clamps may not be suitable or convenient.

Pipe Clamps

Pipe clamps are used to secure cylindrical objects, such as pipes or tubes, during welding. They typically have adjustable jaws that can grip the pipe tightly and provide stability.

Toggle Clamps

Toggle clamps have a lever-operated mechanism that allows for quick and easy clamping. They are commonly used when repetitive clamping is required or when holding irregularly shaped workpieces.