As one of the UK’s leading welding equipment distributors of 50+ years, we understand the importance of providing our customers with high-quality reliable equipment to ensure the best possible outcome and standards for their welding projects. Based on this mindset, we are excited to have recently partnered with Cougartron, a leading manufacturer of stainless steel surface treatment and passivation solutions. The EWS team is thrilled that this partnership extends our offering of top-of-the-range equipment allowing us to take another step toward distributing the tools to build stronger communities. In this post, we’ll take a closer look at how Cougartron’s products can benefit your business.

Why Choose Cougartron as a Partner?

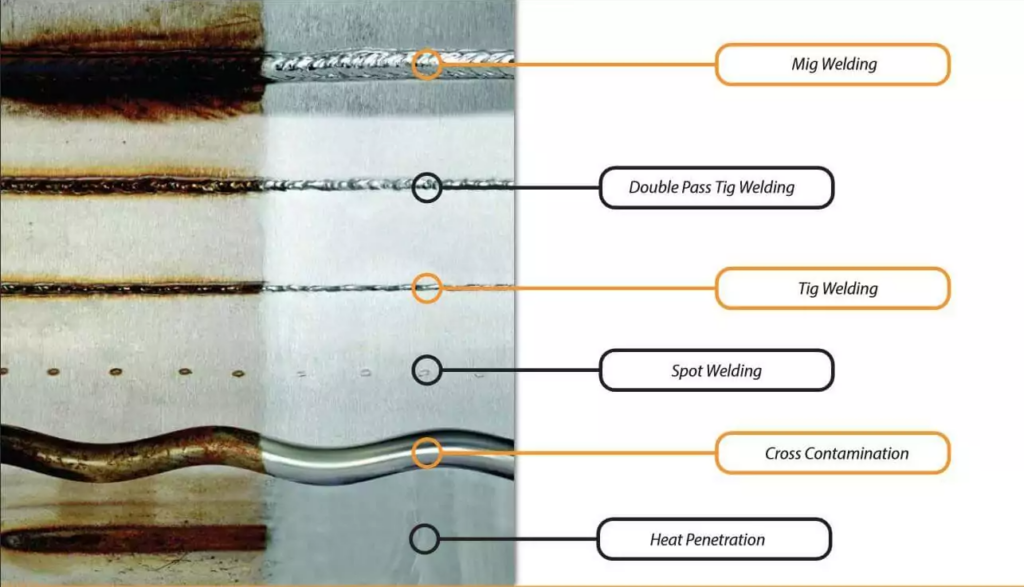

Cougartron offers a wide range of products that are designed to help improve the quality and performance of welds. Their products are specifically designed to make weld cleaning and passivation easier, faster, and more effective. Cougartron’s machines, accessories, and chemicals are renowned for their world-class quality, which gives Cougartron users peace of mind that their welding projects will meet best practice standards.

As a Cougartron premium distributor, we have been given in-depth training, which means we can provide our customers extra support to get the most out of Cougatron’s product range. Our trained team will be available to answer questions and provide guidance on the best products and processes for your specific job requirements.

Benefits of Using Cougartron Products

The key benefits of using Cougartron products for your welding projects are clear and simple.

Flexible: Cougartron’s electrochemical cleaning systems are portable meaning they are an ideal piece of equipment you can take on-site for almost any welding project.

Safe: Cougartron’s cleaning solutions are renowned for being one of the safest methods for stainless steel maintenance. Unlike other cleaning methods, the level of protective equipment required is much less extensive, saving you extra costs related to PPE.

Process speed: Electrochemical weld cleaning is extremely fast. Cougartron machines can clean and passivate the surface at the same time meaning immediate efficiency gains.

Optimal corrosion resistance: Cougartron’s research suggests that compared to other cleaning solutions, such as pickling paste, brushing, and manual grinding, electrochemical weld cleaning is the most effective for rust removal from stainless steel welds.

In summary, Cougartron’s machines, accessories, and chemicals save time and increase overall productivity, all while achieving the highest quality results. Furthermore, customers have the peace of mind that Cougatron’s machines are not only built to last but also backed by a comprehensive warranty, providing confidence that investment in their equipment is protected.

Industries

Cougartron products are used in various industries that rely on welding, including fabrication, shipbuilding, aerospace, food processing, pharmaceutical and medicine, and energy. The popularity of their range across these industries is mainly because their highly effective products pay for themselves through increased productivity and downtime cost savings. Additionally, their weld cleaning technology has been developed with safety in mind, where their equipment is built to enhance safety for operators reducing the risk and cost of workplace injuries. Furthermore, the results of their pioneering technology meet the strict requirements of the most demanding industries. Let’s dig deeper into where Cougarton products fit in for each industry.

General Fabrication

Cougartron’s products are essential for producing high-quality welded components that meet the required standards for appearance and performance. Welded components used in the fabrication industry must be free from imperfections and meet stringent quality standards to ensure their performance and reliability. Cougartron’s cleaning and polishing products are specifically designed to remove oxidation, discolouration, and other surface imperfections from welds, which helps to improve the appearance and integrity of the components. With Cougartron’s weld cleaner range, fabricators can produce high-quality welded components that meet the required standards for appearance and performance, helping to ensure the success of their projects and the satisfaction of their customers.

Shipbuilding

In the shipbuilding industry, a large proportion of repairs/maintenance work can only be carried out while the ship is out of commercial operation. Cougartron’s cleaning, polishing, and marking products are a fast, safe, and efficient stainless steel maintenance solution for marine crews and repair centres.

The harsh marine environment can cause corrosion and other forms of deterioration, which can compromise the integrity of welded components over time. By using Cougartron’s cleaning and polishing products, shipbuilders can remove oxidation, discolouration, and other surface imperfections from welds, which helps to prevent corrosion and improve the overall appearance of the components. Furthermore, Cougartron’s marking range can be used to label and track components throughout the shipbuilding process, ensuring traceability to their original specifications. With Cougartron’s products, shipbuilders can ensure that their welded components are of the highest quality and can withstand the demanding marine environment, helping to improve the safety and reliability of the ships they build.

Aerospace

Corrosion is the most challenging maintenance issue facing the aerospace industry. If thorough maintenance is not conducted regularly the corrosion can compromise the integrity of welded joints and other connections creating the potential for catastrophic failure. Consequently, welded components used in aerospace applications must be able to withstand extreme temperatures and corrosive environments. Cougartron’s cleaning and polishing products are specifically designed to remove oxidation, discolouration, and other surface imperfections from welds, which helps to prevent corrosion and improve the overall appearance of the components. Similarly to the aerospace industry, their marking solutions are ideal for the labelling and tracking of components throughout the aerospace manufacturing process, ensuring complete transparency in the original specifications of components. With Cougartron’s products, aerospace manufacturers can ensure that their welded components meet the high standards required for safety and reliability in the aerospace industry.

Food Processing

Stainless steel is the main metal used within a food and beverage manufacturing setting. Based on this, Cougartron’s products are essential for ensuring that welded components are free from contaminants and meet stringent food safety regulations. Food processing equipment must be able to withstand frequent cleaning and sanitation, which can cause corrosion and other forms of deterioration over time. Cougartron’s cleaning and polishing products are specifically designed to remove oxidation, discolouration, and other surface imperfections from welds, which helps to prevent corrosion and improve the overall appearance of the components. With Cougartron’s products, food processing manufacturers can ensure that their welded components are of the highest quality and meet the strict food safety regulations required in the industry.

Pharmaceutical and Medicine

Cleanliness is fundamental within pharmaceutical and medicine production processes. Failure to adhere to high standards of hygiene creates risk for potential product failure, financial loss, and legal consequences. Welded components in pharmaceutical manufacturing must therefore be free from contaminants and meet stringent quality standards to ensure the safety and efficacy of the final product. With this in mind, Cougatron’s product range is essential for efficient and cost-effective maintenance of welded components used in the production of pharmaceutical products. Furthermore, their marking products are ideal within this industry for labelling and tracking components throughout the manufacturing process, ensuring that they are properly identified and can be traced back to their original specifications. With Cougartron’s products, pharmaceutical manufacturers can ensure that their welded components are of the highest quality and meet the strict regulatory requirements in the industry

Energy

The strict safety and environmental standards within the energy and fuel transport industry are continuously more prominent. Cougartron’s range is a safe and effective solution for maintaining the integrity and safety of welded components used in oil and gas production, refining, and transportation. The harsh and corrosive environment of the oil and gas industry can cause deterioration and compromise the integrity of welded components over time making Cougartron’s weld cleaner products a perfect stainless steel maintenance solution. Additionally, Cougartron’s marking solutions can be used to label and track components throughout the production and transportation process, ensuring that they are properly identified and can be traced back to their original specifications.

Overall, Cougartron’s products are a reliable solution to ensure welded components are high quality and can withstand the unique environmental conditions and requirements of a broad range of industries.

Cougartron products in action

To see the benefits of a few of Cougartron’s products in action, look at the following video demonstrations.

Electrochemical cleaning & polishing solution

Looking for an all-in-one solution, which will deliver superior results for:

- TIG/MIG weld cleaning

- Surface and weld polishing

- Marking and etching?

Check out Cougartron’s ProPlus Weld Cleaner in action below:

Need even more power?

Cougartron Fury100 is a new addition to their weld cleaner Fury line equipped with 100 amps of power, designed to remove the most severe forms of oxidations after TIG and MIG welding.

Let’s see this newest addition in action:

Electrochemical marking & etching solution

Need a more efficient process for labelling and tracking all your metal components?

Is your current method of marking too time-consuming?

Need a more professional and consistent marking system?

Check out Cogatron’s Metal Marking Machine set in action:

Conclusively, if you’re a business or welding professional looking to improve your welding process, increase your productivity, and achieve best practice results for your projects, book a demo with us today to experience Cougartron’s products for yourself.